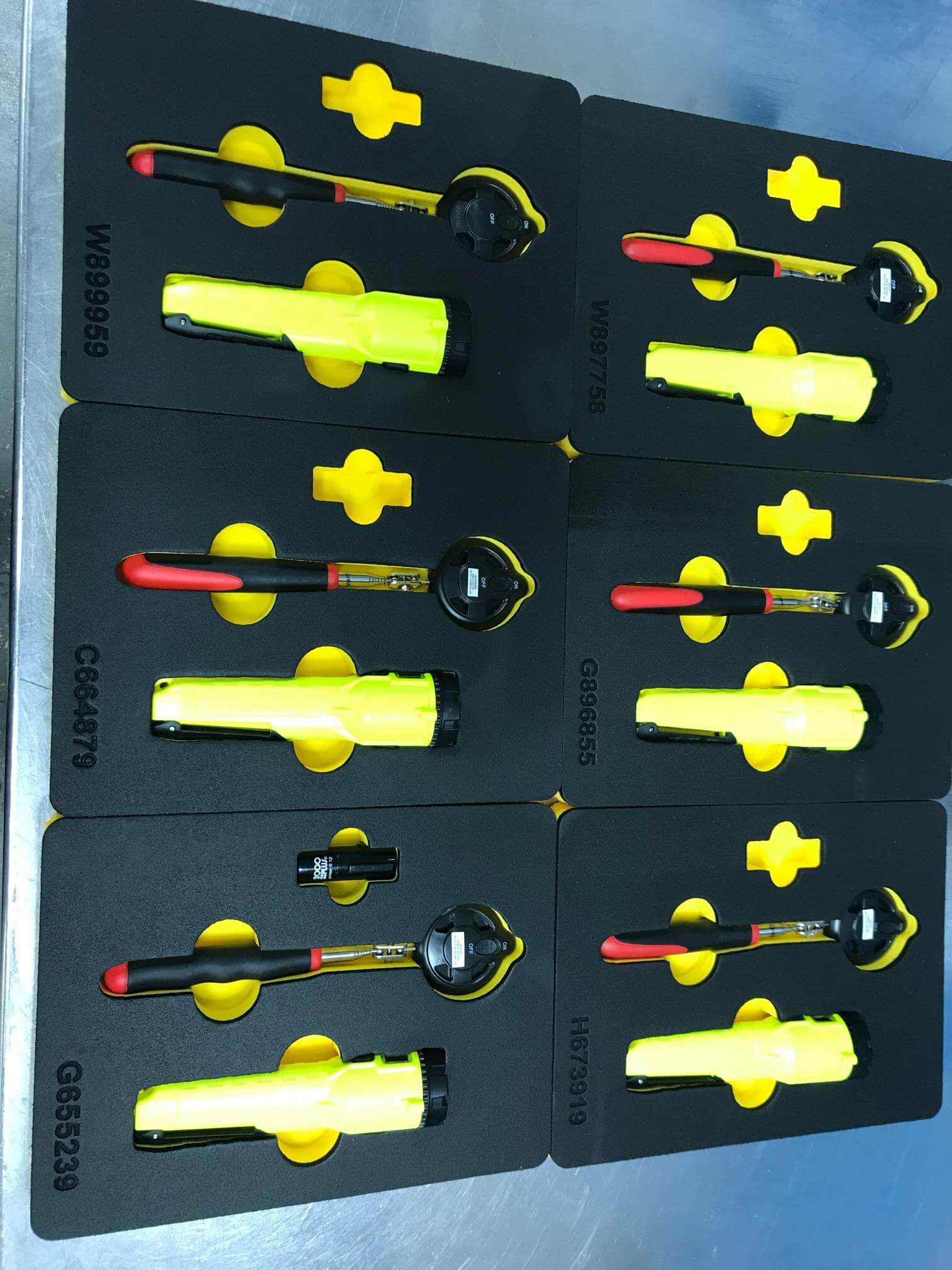

Tool Control

Silver 7 can create custom tool control solutions using high density XLPE foam. We can scan your tools and create exact profiles that can then be laid out in CAD.

We stock a large inventory of foam in many thicknessed, densities, and colors. All our foam is designed to handle the ware and tear of a real-world environment and is resistant to cuts and oils.

Silver 7 can also laser mark your tool as well. We use fiber lasers that can mark of a verity of metals and plastics. We can also mark on the foam with laser or screen printing.